Steps to quality monitoring our business operations to ensure our organisation remains competitive.are":

• Implement operational process improvements

•Measurement of the operative performance

•Collect relevant data

•Analyse all collected information

•Engage your employees

•Establish communication channels and strategies

•Implement new protocols and workflows

Planning is the most critical stage in any project. It guides the stakeholders, teams, sponsors, and project managers on how to go about the other project phases. It helps identify the goals, avoid missing deadlines, prioritizing essential tasks, reduce risks, and deliver the desired results.

Here are some compelling reasons why careful planning is essential in project management.

▪︎Clear Focus and objectives --

Break up the project into smaller tasks for the team to perform and achieve. This ensures everyone focuses on the project’s main goal.

A good project manager clearly defines the roles of all the team members to avoid any confusion and highlights roles that are interdependent. In case any confusion arises, the team can always go back to the plan to clarify.

▪︎Communication--

Proper planning facilitates communication. With proper communication, your team is aware of the tasks they need to perform and the deadlines set to accomplish them.

▪︎Task Dependencies--

Through planning, the project manager can identify tasks that are dependent on each other and schedule them accordingly.

▪︎Planning Resources Allocation--

Through effective planning, the project manager can procure enough resources for the project to run smoothly. This also allows him or her to allocate resources effectively and efficiently and avoid wastage in the long run.

Moreover, effective resource allocation enables the team to run the project within the budget line, often with some cost savings.

▪︎Risk Assessment--

You can’t know what challenges you might face in the course of the project if you don’t prepare yourself beforehand. However, a good plan allows you to conduct a risk assessment and establish contingencies to help you overcome them.

▪︎Planning Project Milestones --

A good plan must include milestones to help the project manager monitor the project’s progress.

Moreover, a good plan will also provide opportunities to re-evaluate deadlines, scope, and deliverables, thereby making adjustments where necessary.

Monitoring::

Project Monitoring refers to the process of keeping track of all project-related metrics including team performance and task duration, identifying potential problems and taking corrective actions necessary to ensure that the project is within scope, on budget and meets the specified deadlines.

When project managers make important decisions without verified data, it is like taking a stab in the dark. Your decisions will be based on very little to no evidence so the action may not be very efficient and could only be a waste of time and resources.

That’s why it is important to monitor projects diligently and use the data you gathered to come up with intelligent decisions.

Here are some questions answered through project monitoring:

- Are tasks being carried out as planned?

- Are there any unforeseen consequences that arise as a result of these tasks?

- How is your team performing at a given period of time?

- What are the elements of the project that needs changing?

- What is the impact of these changes?

- Will these actions lead you to your expected results?

Automated tools and technologies can simplify the tedious process of project monitoring. Most project managers have already adapted project management tools to delegate tasks and monitor their projects. However, project monitoring is a complex process and there are only a few project management apps out there that can support the project manager’s requirement to have laser-focus on individual tasks and team efficiency.

Control in their methodoligies::

The feature of project control for project management and they are

•Work Breakdown Structure (WBS)

The project management methodologies list are:

•Waterfall methodology

•Agile methodology

•Scrum methodology

•kanban methodology

•scrumban methodology

•Extreme programming (XP) methodology

•Adaptive Project framework (APF) methodology

•Lean Methodology

•critical patg method

•Critcal Chain Project management

• New Product introduction

•Package enabled reengineering

•Outcome mapping

•Six Sigma

•PMI's PMBOK

•PRINCES2 Methodology

•Rapid application development methodologies.

1. Schedule

The operations manager has day-to-day management responsibilities and many of those tasks will take place on a business as usual schedule. vs. The project manager is responsible for ensuring that the project stays on time.

2. Budget

An operational manager is responsible for the department budget and the overheads related to running that department. vs. A project manager is responsible only for the budget relating to the particular project that he or she is working on at the time.

3. State

An operational manager has one single state to work with. vs. A project manager moves from one state to another i.e. results in change, moreover, the task is to become a perfect conductor between departments.

4. Period of time

An operational manager can not say about the real start and end points of his work. vs. A project manager has a definable start and end points (limited by the time of a project)

5. The main purpose

An operational manager is a product or process oriented vs. Obviously project orientation of a PM.

The similarities between porject managment and operation management are :-

* Both are performed by individuals.

* Both are planned , executed and controlled.

* Both are designed to meet the organizational and the strategic objectives.

* Both are subject to constrains such as schedule and resources.

Examples from and multi-sources industry sectors are:-

Task 3of 4

Kaizen ::

In our distribtion step to acheving sucess in modern distrubtion getting the basic right these business areas:

- The ability to profile customers and buying trends

- Inventory optimisation for improved cashflow

- Optimising fulfilment rates

- Recognising and reducing errors

- Achieving on-time delivery

- Increase average order sizes

- Lowering or controlling costs

- Facilitating internal and external collaboration across the supply chain

● Inventory Management

The just-in-time(JIT) inventory system is a management strategy that aligns raw-material orders from suppliers directly with production schedules. Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process, which reduces inventory costs. This method requires producers to forecast demand accurately.

The JIT inventory system contrasts with just-in-case strategies, wherein producers hold sufficient inventories to have enough product to absorb maximum market demand.

JIT inventory management strategy has a number of potential benefits for businesses:

- Lower inventory holding cost – with inventory purchased or produced at short notice there’s no need to have unsold inventory taking up valuable warehouse space.

- Improved cash flow – without the need to store large volumes of inventory at all times, capital expenditure is reduced, and cash can be invested elsewhere.

- Less dead stock – because inventory levels rely on customer demand, there’s less risk of unwanted stock left sitting in your warehouse.

- JIT aims at keeping the stock holding to bare minimum leading to much lower inventory cost and much lower storage and warehouse cost.

- Minimum inventory at all stages of supply chain means lesser expiry and lesser wastage for the organization.

- JIT manufacturing aims at producing items based on the demand. Hence all items produced will be sold. So no obsolete items in the finished goods section. It helps the organization to adapt well to any changes in product specification from the market without the fear of having any kind of waste and obsolete stocks.

- To achieve JIT production, there is a need for very close communication between all the parties involved in the entire supply chain. This communication technique is often referred as “Kanban”.

- In JIT, immense focus is on quality of the final product and companies work to achieve “first time right” for all goods.

- JIT production can be very sensitive to any kind of error. Since bare minimum inventory levels are maintained, there is no room for any kind of error.

- JIT production will not be able to adapt well to sudden increase in volume of demand from the market, since the inventory levels are maintained at much lower level.

- Just in time manufacturing is a philosophy which is achieved only when all the parties involved in the whole supply chain will work in great tandem and coordination. JIT may fail sometime if any of the suppliers will fail to fulfil their obligations and respond to the requirements in a timely manner.

● Logistic

JIT applied to production systems increases the pressure on logistics, which needs to work with maximum efficiency. JIT methodology makes it essential for the relationship between different suppliers (raw material, components, services) and its B2B customers to be fluid, with open and efficient communication.

With the globalisation of markets, greater competitiveness and the boom in electronic commerce, consumers demand greater variety in products and reduced delivery times.

The Just-in-Time system has spread its application beyond production systems since just-in-time logistics is spoken of in customer service, order preparation inventory management and transport.

In supply chain management (SCM) it is necessary to have warehouses at those points in the chain where the goods have to stop, either to store them until they are sold or waiting for their distribution or temporary storage awaiting transport.

Warehouses also have to follow JIT principles, making it necessary to eliminate anything that could be considered to be unnecessary; speeding up picking tasks in the preparation of orders by using automated system which reduce inventory errors, speeding up tasks related to reverse logistics, optimising the routes for fork lift trucks or warehouse workers and using the most suitable metal racking systems for each level of rotation and goods flow.

● Distribution :

SIX SIGMA :-

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986. Jack Welch made it central to his business strategy at General ectric in 1995. A six sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects.

● Inventory Management :

Inventory management plays two critical roles in Lean Six Sigma. Firstly, the management of raw materials and semi-finished goods in the lean manufacturing process. Secondly, inventory control of finished goods held in a warehouse by manufacturers.

As a component of lean manufacturing, stock levels of raw materials and semi-finished products need to be controlled and managed.

This will reduce waste and optimize the production workflow.

Accordingly, Lean Six Sigma is used to identify and eliminate these root causes.

A. Lean Six Sigma in Action :

Root causes in inventory management can be described as higher and lower-level root causes. Often, excess stock, dead stock and obsolete inventory is caused by higher-level root causes. These include purchasing lead times, forecasting, quality and design issues. Consequently, these can then be broken down further into lower-level root causes.

B. Lean Inventory Management For the Future :

Just as Six Sigma evolved into Lean Six Sigma for today’s decade, it stands to reason that lean management principles equally apply to inventory management. This results in Lean Inventory Management principles for businesses outside of manufacturing. This is especially so for wholesalers, distributors and retailers who deal in physical goods.

Lean management, or Lean for short, is an approach to running an organization that supports the concept of continuous improvement.

Using lean principles in inventory management can result in quantifiable improvements for small and medium-sized businesses.

C. Principles of lean Inventory Management:

Like Six Sigma, there are five guiding principles in Lean Inventory Management. You can recognise some from past quality management and manufacturing principles of the past decades. Thus so, methodologies can adapt and evolve to suit pressing issues that businesses face today.

- Value. Identify the value that a company will get from Lean Inventory Management.

- Flow. Optimize the flow of inventory through the business by removing obstacles in the way. This comes from the Japanese 5S Lean principle (Sort, Straighten, Sweep, Standardize, Sustain).

- Pull. Move inventory only when requested by the customer. This is adapted from the Kanban Lean principle.

- Responsiveness. Be flexible and adapt to change. This is influenced by the Kaizen Lean principle.

- Perfection. Continuously refine your inventory management processes to improve quality, cycle time, efficiency and cost.

- Demand management: we should only move inventory upon an order by a customer.

- Cost and waste reduction: But not to the extent of negatively affecting the customer.

- Process standardization : Standardizing, for example, on transportation and business processes.

- Industry standardization: Standardizing on product parts and components.

- Cultural change : Everyone along the supply chain must work as a team. Similarly, this echoes principles from Just-in-Time manufacturing.

- Cross-organization collaboration : Teams that cut across the organization can help to understand value better.

● Distribution :

Six Sigma is a data-driven approach to problem-solving.

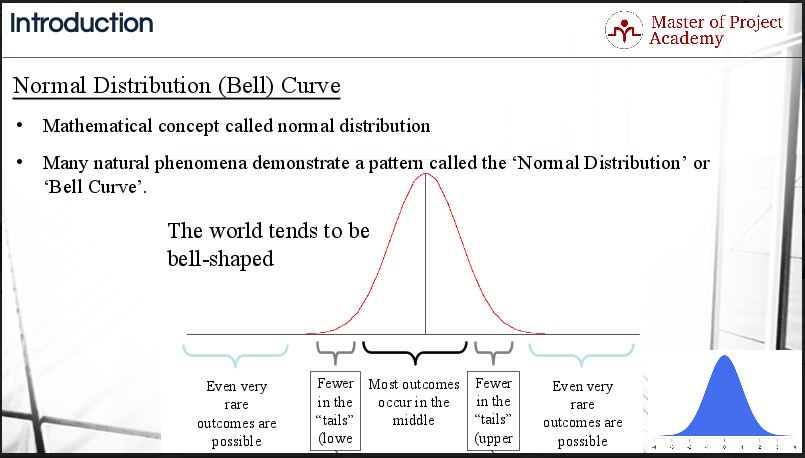

The term “Normal Distribution Curve” or “Bell Curve” is used to describe the mathematical concept called normal distribution, sometimes referred to as Gaussian distribution. It refers to the shape that is created when a line is plotted using the data points for an item that meets the criteria of ‘Normal Distribution’.

The structure of a normal distribution curve. The center contains the value where the value of the greatest number of data points occur and therefore would be the highest point on the arc of the line. This point of the normal distribution curve is the mean or average.

The normal distribution curve is one of the most important statistical concepts in Lean Six Sigma. Lean Six Sigma solves problems where the number of defects is too high. A high number of defects statistically equals high variation in the process. The normal distribution curve visualizes the variation in a dataset.

● Logistic :

Six Sigma Logistics has become the backbone for any business these days as it provides that important competitive advantage in the market, for any company. The Six Sigma approach of eliminating the defects or minimizing the variations in a process can be very handy if applied to logistics. This is because such an approach can increased the satisfactiob level of both external and internal clients and in turn can result in financial benefit.

• DMAIC or Define-Measure-Analyze-Improve- Control is one such method, devised for seamless assimilation of the Six-Sigma approach to logistics. It overhauls and improves the entire internal logistical process and ensures reduction of defects. It also reduces the mean route time and the route time variability.

• Variation reduction and logistics

In any business that involves logistics, variation reduction is an important concept. Logistics is all about managing inventory and this depends heavily on managing variance.

It is evident that for Six Sigma to be successful in logistics, it should be driven with a sustained focus on quality improvement and customer relations.

MRP ::

Material requirements planning (MRP) is a production planning, scheduling and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

●Inventory management

Material requirements planning (MRP) is a computer-based inventory management system designed to assist production managers in scheduling and placing orders for items of dependent demand. Dependent demand items are components of finished goods—such as raw materials, component parts, and subassemblies—for which the amount of inventory needed depends on the level of production of the final product.

The first MRP systems of inventory management evolved in the 1940s and 1950s. They used mainframe computers to explode information from a bill of materials for a certain finished product into a production and purchasing plan for components. Before long, MRP was expanded to include information feedback loops so that production personnel could change and update the inputs into the system as needed.

● Manufacturing :

A critical input for material requirements planning is a bill of materials (BOM) —an extensive list of raw materials, components, and assemblies required to construct, manufacture or repair a product or service. BOM specifies the relationship between the end product (independent demand) and the components (dependent demand). Independent demand originates outside the plant or production system, and dependent demand refers to components.

Companies need to manage the types and quantities of materials they purchase strategically; plan which products to manufacture and in what quantities; and ensure that they are able to meet current and future customer demand—all at the lowest possible cost. MRP helps companies maintain low inventory levels. Making a bad decision in any area of the production cycle will cause the company to lose money. By maintaining appropriate levels of inventory, manufacturers can better align their production with rising and falling demand.

● Distribution

Material requirements planning (MRP) and distribution requirements planning (DRP) calculates organization-specific net requirements from gross requirements by evaluating:

- the master schedule

- bills of material

- sourcing rules

- supply chain bills

- scheduled receipts

- on-hand inventory balances

- production and transportation lead times

- order modifiers

MRP Logistics in the business of cargo movements on Door-to-Door basis through Air, Train and Surface and delivering goods. We have our team of logistics professionals and many companies are availing our services in logistics solutions. They are getting hassle free logistics services enable them to concentrate on their competitors. We are also proving door-to-door local deliveries to many companies dealing in the business of information technology.

Kanban ::

Kanban definition. Initially, it arose as a scheduling system for lean manufacturing, originating from the Toyota Production System (TPS). In the late 1940s, Toyota introduced “just in time” manufacturing to its production.

Kanban is a workflow management method for defining, managing and improving services that deliver knowledge work. It aims to help you visualize your work, maximize efficiency, and improve continuously. From Japanese, kanban is translated as billboard or signboard. Originating from manufacturing, it later became a claimed by Agile software development teams.

● Inventory Management

Kanban isan inventory scheduling system that allows companies to stock only needed components and arts in the production or distribution process. In lean manufacturing, the process pulls materials through the production or distribution process. The Kanban system provides a signal for reordering or replenishing stock.

The goal of a Kanban inventory system is to continually maintain the minimum amount of stock. The beauty of the way the supermarket managed its inventory was that it only stocked items it expected to sell them in a given time.

It is a tool for lean manufacturing that aims to prevent inventory pileup by initiating production only to restock empty reserves.

● Distribution ::

Kanban isan inventory scheduling system that allows companies to stock only needed components and arts in the production or distribution process. In lean manufacturing, the process pulls materials through the production or distribution process. The Kanban system provides a signal for reordering or replenishing stock.

●Logistic ::

The literal translation of Kanban in Japanese is “signboard.” This is because, originally, poster board cards were used to request the parts that were needed from the previous process.

Advangtage of the kanban method in logistics and production :

The Kanban system is a perfect match for the just-in-time method because it:

- Allows you to visualize the work being carried out and, thus, easily identify each stage of the production or replenishment cycle.

- Enables you to set work in progress (WIP) limits to prevent bottlenecks.

- Lets you measure lead time between processes, that is, the time it takes to complete each phase.

- Works, by linking the various stages, as a control system for production and for the materials available in the different warehouses.

- Prevents overproduction and excess stock, thereby saving storages space .